Ubora wa Juu 18*64mm G80 Iliyopakwa Rangi Nyeusi Mnyororo wa Uchimbaji wa Kiungo

Ubora wa Juu 18*64mm G80 Iliyopakwa Rangi Nyeusi Mnyororo wa Uchimbaji wa Kiungo

Kategoria

Maombi

Bidhaa Zinazohusiana

Parameta ya mnyororo

Kama mtengenezaji wa mnyororo wa chuma wa pande zote kwa miaka 30, kiwanda chetu kimekuwa kikikaa na kutumikia kipindi muhimu sana cha mageuzi ya tasnia ya utengenezaji wa mnyororo wa Kichina katika uchimbaji wa madini (madini ya makaa ya mawe haswa), kuinua vitu vizito, na mahitaji ya kusambaza viwandani kwenye minyororo yenye nguvu ya pande zote za chuma. Hatuishii tu kuwa watengenezaji wanaoongoza wa minyororo ya viungo vya duara nchini Uchina (tukiwa na usambazaji wa kila mwaka zaidi ya 10,000T), lakini tunashikilia uundaji na uvumbuzi usiokoma.

SCIC Round Link Chain inafanywa kulingana na kiwango cha China GB/T-12718 na Mahitaji ya Kiufundi ya kiwanda, pamoja na viwango vya DIN 22252 au GOST 25996 na vipimo vya wateja.

SCIC Round Link Chain inatumika kwa Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), mashine za vichwa vya barabara, jembe la makaa ya mawe na vifaa vingine vinavyohitaji aina hii ya mnyororo.

Mipako ya kuzuia kutu (kwa mfano, mabati yaliyochovywa moto) husababisha kupungua kwa sifa za mitambo ya mnyororo, kwa hivyo utumiaji wa mipako yoyote ya kuzuia ulikaji itategemea makubaliano ya agizo kati ya mnunuzi na SCIC.

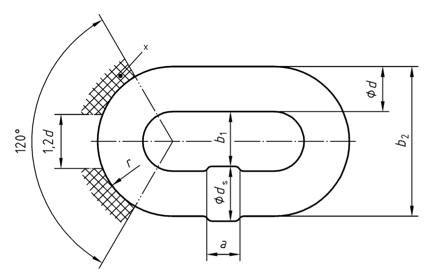

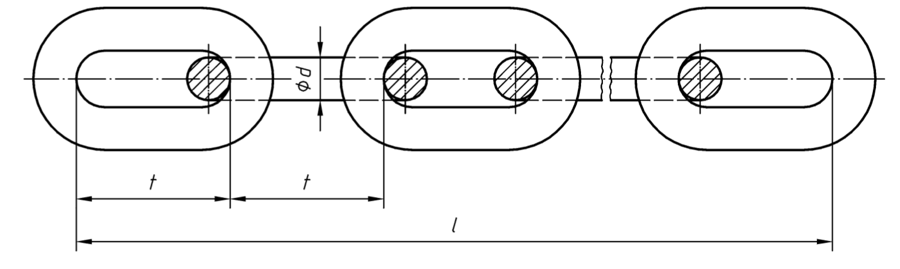

Kielelezo 1: mlolongo wa kiungo cha pande zote

Jedwali la 1: vipimo vya mnyororo wa kiunga cha pande zote

| saizi ya kiungo (opp. Weld) | lami | upana wa kiungo | saizi ya weld ya kiungo | uzito wa kitengo | ||||

| jina | uvumilivu | jina | uvumilivu | ndani | nje | kipenyo | urefu | |

| 10 | ± 0.4 | 40 | ±0.5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ±0.5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0.5 | 64 | ±0.6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0.6 | 64.5 | ±0.6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0.7 | 86 | ±0.9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0.8 | 86 | ±0.9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0.8 | 92 | ±0.9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0.9 | 108 | ±1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ±1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ±1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ±1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ±1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ±1.5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ±1.5 | 46 | 133 | 45 | 30 | 35.3 |

| maelezo: Lmnyororo wa saizi ya arger unapatikana wakati wa uchunguzi. | ||||||||

Jedwali la 2: mali ya mitambo ya mnyororo wa kiunga cha pande zote

| saizi ya mnyororo | daraja la mnyororo | nguvu ya mtihani | elongation chini ya nguvu ya mtihani | kuvunja nguvu | elongation katika fracture | mchepuko mdogo |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64.5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810 | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810 | |||

| SCC | 1810 | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740 | 14 | 42 |

| SC | 1770 | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |